Industry is changing

Many technologies revolve around industry 4.0 and mechanical engineering. Most of them are digital, hence their significant impact.

This impact concerns:

- the possibility of connecting everything to collect data, the notion of IoT (Internet of Things, but not only…)

- the development of decentralized infrastructures (referring to “cloudification”)

- data analysis such as machine learning

- Several technologies now represent an evolution within the industry

These are the possibilities offered by electronic integration, cobotics, virtual and augmented reality, gamma-ray NDT, etc. Ultimately, technological disruptions are unfolding.

The combination of artificial intelligence, vision systems, new cognitive interfaces and blockchain, some of which should revolutionize the industrial world and by the end, making the maintenance of industrial robots easier over time with impressive evolution of techno and mechanical engineering.

Addressing the subject by focusing on 2 fundamental aspects:

- The customer’s need or usage

- The market segment approach associated with the customers’ process knowledge

Value creation through innovation

Usage-based solutions and services by combining process knowledge and the best technologies of the moment. Actemium can apply a mechanical engineering approach to the plant of the future in 5 aspects:

-

- Equipment & Systems

- Processes

-

- Business Process Management (BPM)

- Remote Expert

- Digital Twin

- Location-based Services

- Health & Safety

-

- Robotics & Cutting edge solutions

- Additive Manufacturing

-

- IT-OT Value Chain

- Cybersecurity

- Cloud Services

- MOM (New style MES)

-

- Energy Efficiency

- Circular Industry

- Decarbonizing Industry

- Financing

To address the five main drivers of the industry of the future:

- Quality, with a need to move up the range

- Reliability, the key to efficient (and safe) production

- Productivity, greater competitiveness

- Flexibility, to be able to adapt to demand and produce at will, thanks to industrial automation.

- Sustainability, which includes environmental aspects

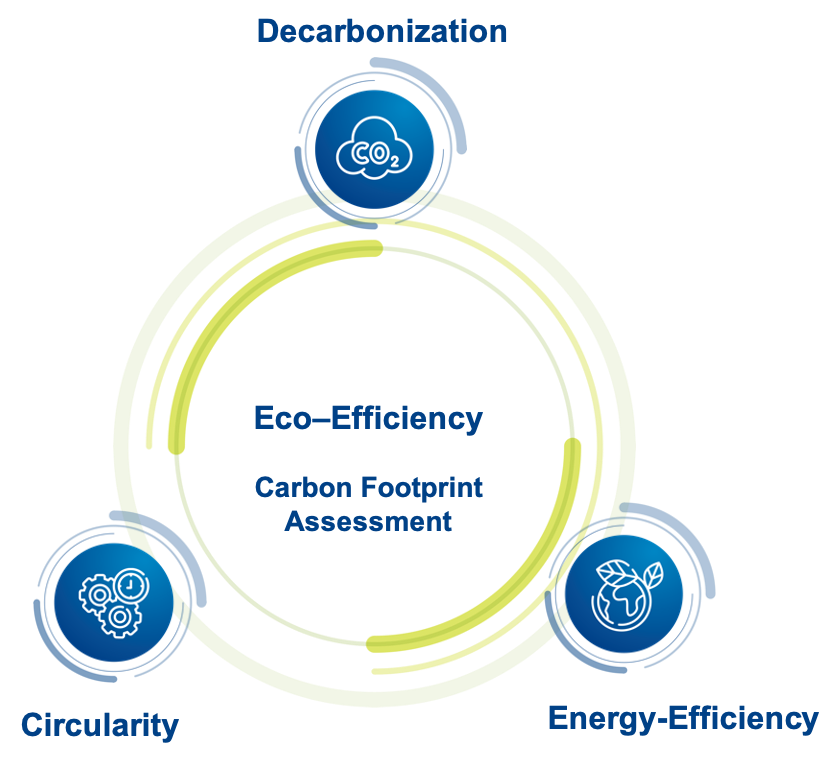

Act for sustainability

Eco-Efficiency is a major concern in all Actemium projects. It’s the combination of Energy-efficiency, Circularity and Decarbonization; with the main indicator: the Carbon footprint. The development of this tool is a priority.

Three ways to improve the impact of industries in the world

-

Energy-Efficiency

-

Circularity

-

Decarbonization